What Does Dust Extractor Vs Shop Vac Do?

Table of ContentsThe 9-Second Trick For Dust Extractor Vs Shop VacSome Known Incorrect Statements About Dust Extractor Vs Shop Vac Getting My Dust Extractor Vs Shop Vac To WorkWhat Does Dust Extractor Vs Shop Vac Mean?Rumored Buzz on Dust Extractor Vs Shop VacEverything about Dust Extractor Vs Shop Vac

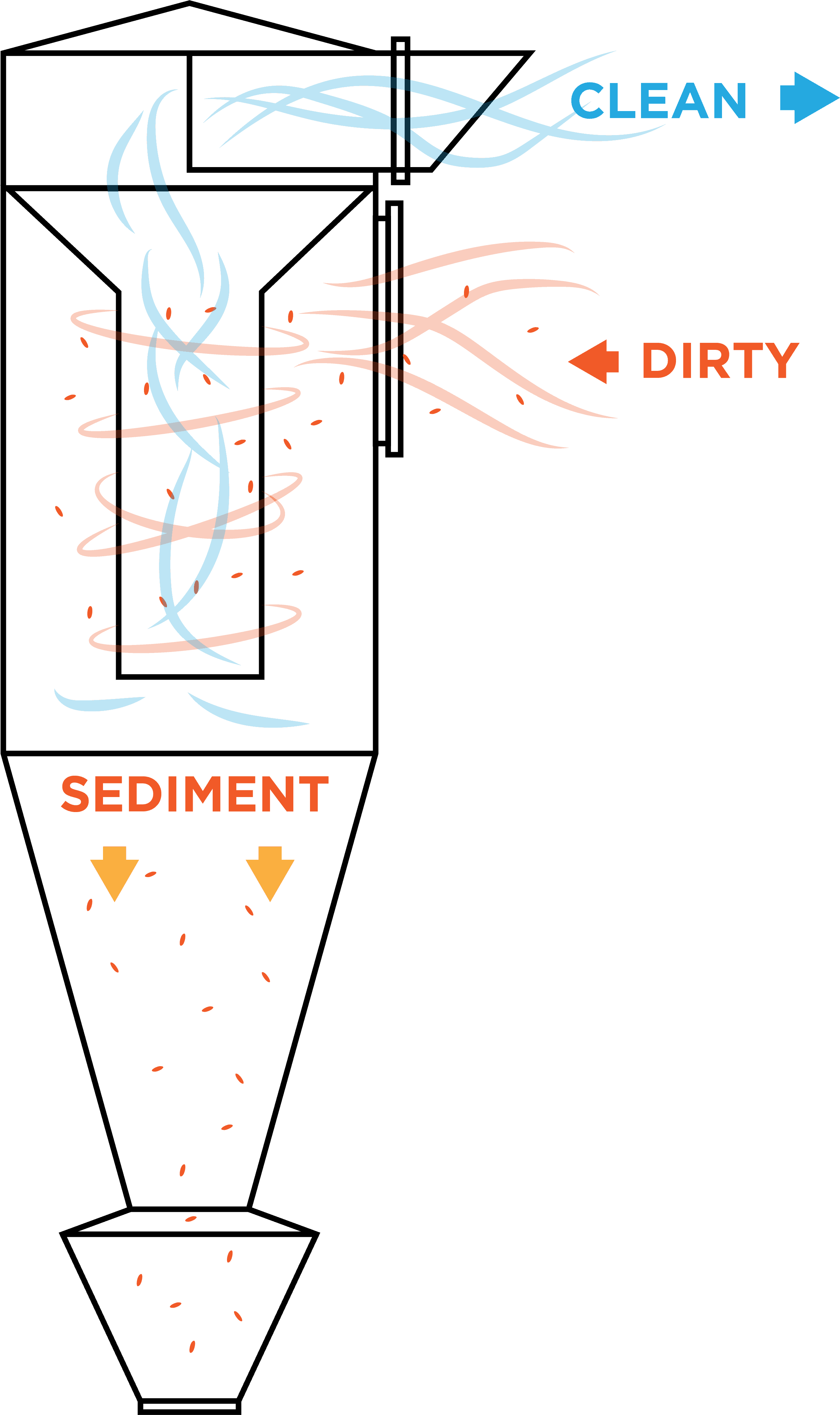

The design of the 2 systems is to meet the needs of various air filtering system procedures. With a horizontal system, unclean air gets in the cartridge at high rate.

The horizontal system allows for irreversible as well as perfect cartridge placement without yokes, sagging, or breaking. Gaskets create a tight and also safe and secure seal along the real estate as well as filters. Vertical cartridge dirt collecting system replaces bags with round or oval-shaped cartridges that are open on both ends and also are lined with pleated filtering media.

The Single Strategy To Use For Dust Extractor Vs Shop Vac

The air stream is forced through the exterior of the cartridge to the inside. The cartridges are maintained tidy by compressed air blown into them, which removes built-up dust that comes under the hopper listed below. A damp scrubber dust collection system utilizes droplets of water to record the dirt bits.

The Single Strategy To Use For Dust Extractor Vs Shop Vac

A feasible solution for dust collection for processes that produce dirt as component of production and processing is a self-contained, inner return dust collection system that utilizes a collection of followers, filters, as well as collection bags to eliminate dirt from workstations and production. They are a favorable stress bag collector made use of in facilities where bits do not get to the submicron level.

This kind of system is the least costly and extremely efficient - dust extractor vs shop vac. It is developed to collect wood chips, plastic particles, and also products that collect their website on strong surfaces. On top of that, the system is completely self-supporting, indicating that it does not discharge air right into the atmosphere as well as can be found in sizes to fit any kind of operation.

The effectiveness of an ambient dirt collection system can change the air in a structure. A capture system that uses hoods, arms, and capture factors is part of an ambient dirt collection system. As the cleaned up air go back to a building, it compels unclean air right into the ambient dust collection system.

Dust Extractor Vs Shop Vac Things To Know Before You Buy

The system is capable of removing fugitive dirt or fumes from portable resources. In shops with variable production, 2 or more small systems may be better to one huge system.

The primary attribute of a push-pull ambient system is cleaning up the air and returning it. This is unlike a system that cleanses the air and releases the tidy air outside the structure, which can be inefficient. The push-pull method is highly effective and energy-saving and also benefits from home heating as well as cooling systems that do not exist with air being aired vent outside.

The setup of NPBI technology improves indoor air top quality for healthier working conditions. Filters supply purification for the air while the ionizers take the exhaust and also give it passive air filtration to enhance the air being gone back to the building. The ions from the system move in the airstream as well as clean the air anywhere, also in undetected places.

Some Known Details About Dust Extractor Vs Shop Vac

As they enter the airstream, they connect to bits, microorganisms, gasses, as well as smells, consisting of submicron particles. The particles come to be brought in per other and also are big sufficient to this post be conveniently filteringed system. The ions kill the bits by eliminating their hydrogen, which is important for their presence. Filtration systems are a prominent kind of dirt collection, there are systems that do not use filters.

As bits travel through the system, they are ionized as well as charged, which causes them to be gathered on an accumulating plate. From the collecting plate, the bits are eliminated by rapping or vibration. The procedure can be seen in the layout listed below. Electrostatic precipitator dirt collectors (ESPS) work with large air movement.

An issue with ESPS systems is how slowly particles tackle an electric charge. For the system to be reliable, the particles airborne must can taking on a charge swiftly for fast elimination. The main feature of dirt collection agencies is to collect dirt and also tidy the air. dust extractor vs shop vac.

The 9-Second Trick For Dust Extractor Vs Shop Vac

These threats require special explosion-proof dust collection agencies that have systems to stop as well as control explosive materials. The initial step in selecting an explosion-proof dust collection system is identifying the kinds of dust a procedure develops. Different kinds of dust have to be controlled as well as monitored in different ways in order to be controlled - dust extractor vs shop discover this info here vac.

It is essential to recognize that all natural dust is eruptive and also calls for an explosion-proof dirt collection agency. In situations with prospective explosive or combustible bits, the procedure begins with "go or no go" screening, where dust is sent out to be evaluated. The process aids in selecting the correct dirt accumulating system.